790050_DOUBLE EFFECT PNEUMATIC ACTUATOR_ALUMINIUM

DOUBLE EFFECT PNEUMATIC ACTUATOR IN ALUMINIUM NICKEL – 90°

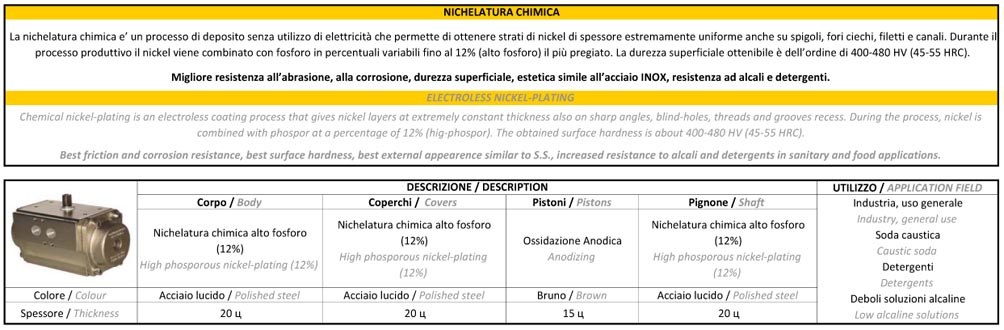

•ENAW 6063 T6 extruded Aluminium Body, inside surface finish Ra=0,4-0,6 and treatment of Nickel plating.

•ENAB 46100 T6 die-casted Aluminium alloy Pistons, 15 micron Anodizing.

•ENAB 46100 T6 die-casted Aluminium alloy Covers Nickel plated.

•Carbon steel Shaft, 20 micron Nickel plated.

•Screws in Stainless Steel AISI 304 (A2).

•Seals in nitrile nubber NBR.

•LAT-LUB low friction sliding Bearings.

•High performances Syntetic Grease.

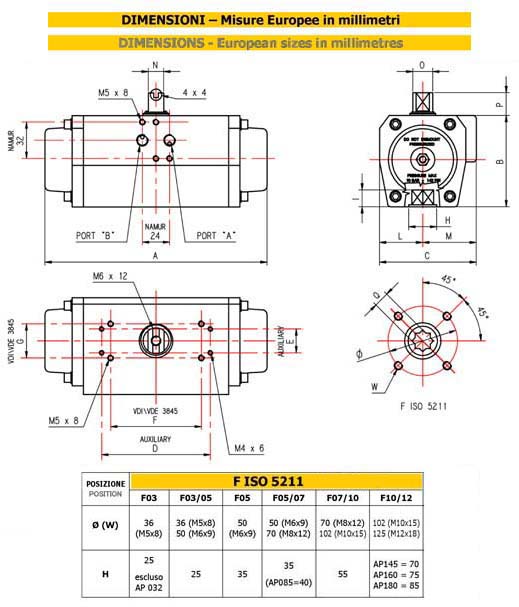

•Double lower drilling for valve fastening and centering according to ISO 5211-DIN 3337 standards.

•Double square lower female shaft key (starlike) according to ISO 5211-DIN 3337 standards to assembly on valves with square key on line (0°) and diagonal key (45°).

•Solenoid connections according to NAMUR VDIVDE-3845 standards.

•Top drilling for accessories fastening, and upper shaft end according to NAMUR VDIVDE-3845 standards.

•3D position indicator.

•Aluminium adhesive nameplates with progressive serial number punched.

•Lubrification guaranteed for min. 1.000.000 operations.

•Running test and 100% seal test carried out with electronic equipment and certification of each individual product.

•According to ATEX 2014/34/UE Standard for explosive environnement; STANDARD version actuator: II 2GD c Tmax = 95°C.

•According to EN 15714-3 design and manufacture standard requirements.

USE:

AIR SUPPLY: dry or lubricated filtered compressed air.

TEMPERATURE RANGE: -20°+80°C

FEEDING PRESSURE: 8 bar/120 psi continuous – 10 bar/142 psi maximum.

TURNING ROTATION RANGE: +/- 5°.

STANDARD ROTATION: counterclockwise.

| TYPE | 1 BAR | 2 BAR | 3 BAR | 4 BAR | 5 BAR | 6 BAR | 7 BAR | 8 BAR | 9 BAR | 10 BAR | CODE |

|---|---|---|---|---|---|---|---|---|---|---|---|

| AP 032 | - | - | - | 5,0 | 6,3 | 7,6 | 8,8 | 10,0 | 11,4 | 12,6 | 790050 80500 3D |

| AP 042 | - | - | 6,5 | 8,7 | 10,9 | 13,0 | 15,2 | 17,3 | 19,5 | 21,7 | 790050 80700 3D |

| AP 050 | 3,0 | 6,1 | 9,2 | 12,3 | 15,4 | 18,5 | 21,5 | 24,6 | 27,7 | 30,8 | 790050 81000 3D |

| AP 063 | 5,5 | 11,0 | 16,5 | 22,0 | 27,5 | 33,0 | 38,5 | 44,0 | 49,5 | 55,0 | 790050 81600 3D |

| AP 075 | 11,7 | 23,4 | 35,1 | 46,8 | 58,5 | 70,2 | 81,9 | 93,6 | 105 | 117 | 790050 82000 3D |

| AP 085 | 17,8 | 35,6 | 53,4 | 71,2 | 89,0 | 107 | 125 | 142 | 160 | 178 | 790050 82500 3D |

| AP 100 | 27,7 | 55,4 | 83,2 | 111 | 139 | 166 | 194 | 222 | 250 | 277 | 790050 83000 3D |

| AP 115 | 45,7 | 91,5 | 137 | 183 | 229 | 275 | 320 | 366 | 412 | 458 | 790050 83500 3D |

| AP 125 | 60,1 | 120 | 181 | 241 | 301 | 361 | 421 | 481 | 542 | 602 | 790050 84000 3D |

| AP 145 | 86,7 | 173 | 260 | 347 | 434 | 520 | 607 | 694 | 780 | 867 | 790050 84500 3D |

| AP 160 | 118 | 237 | 355 | 473 | 592 | 710 | 828 | 947 | 1065 | 1183 | 790050 85000 3D |

ACTUATOR TORQUE IN Nm

| POSITION | AP 032 | AP 042 | AP 050 | AP 063 | AP 075 | AP 085 | AP 100 | AP 115 | AP 125 | AP 145 | AP 160 | AP 180 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A-90° | 100 | 139 | 139 | 152 | 205 | 230 | 275 | 309 | 360 | 392 | 462 | 482 |

| B | 45 | 57 | 68 | 83,5 | 100 | 110 | 125 | 142 | 155 | 175 | 196 | 220 |

| C | 49 | 60,5 | 75 | 86 | 94 | 104 | 120 | 134 | 141 | 163 | 176 | 196 |

| D x E | - | - | - | - | 105 x 22 | 105 x 22 | 105 x 22 | 139 x 22 | 139 x 22 | 139 x 22 | 139 x 22 | 139 x 22 |

| F x G | 50 x 25 | 80 x 30 | 80 x 30 | 80 x 30 | 80 x 30 | 80 x 30 | 80 x 30 | 130 x 30 | 130 x 30 | 130 x 30 | 130 x 30 | 130 x 30 |

| L | 23,5 | 27 | 33,5 | 38 | 42,5 | 49 | 55 | 63,5 | 69,5 | 80 | 88 | 98 |

| M | 25,5 | 33,5 | 41,5 | 48 | 51,5 | 55 | 65 | 70,5 | 71,5 | 83 | 88 | 98 |

| Port.A-Port.B DIN259 | 1/8" GAS | 1/8" GAS | 1/8" GAS | 1/4" GAS | 1/4" GAS | 1/4" GAS | 1/4" GAS | 1/4" GAS | 1/4" GAS | 1/4" GAS | 1/4" GAS | 1/4" GAS |

| N x O | 8 x 12 | 8 x 12 | 8 x 12 | 8 x 12 | 14 x 18 | 14 x 18 | 14 x 18 | 27 x 36 | 27 x 36 | 27 x 36 | 27 x 36 | 32 x 42 |

| P | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 30 | 30 | 30 | 50 | 50 |

| Q x I | 9 x 10 | 9 x 10 11 x 13 | 9 x 10 11 x 13 | 9 x 10 11 x 13 14 x 16 | 11 x 13 14 x 16 17 x 20 | 14 x 16 17 x 20 | 14 x 16 17 x 20 22 x 25 | 17 x 20 22 x 25 | 17 x 20 22 x 25 27 x 30 | 22 x 25 27 x 30 | 22 x 25 27 x 30 | 27 x 30 36 x 39 |

| F.ISO 5211 | F03 | F04 | F04 | F05 | F05 / 07 | F05 / 07 | F07 / 10 | F07 / 10 | F07 / 10 | F10 / 12 | F10 / 12 | F10 / 12 |

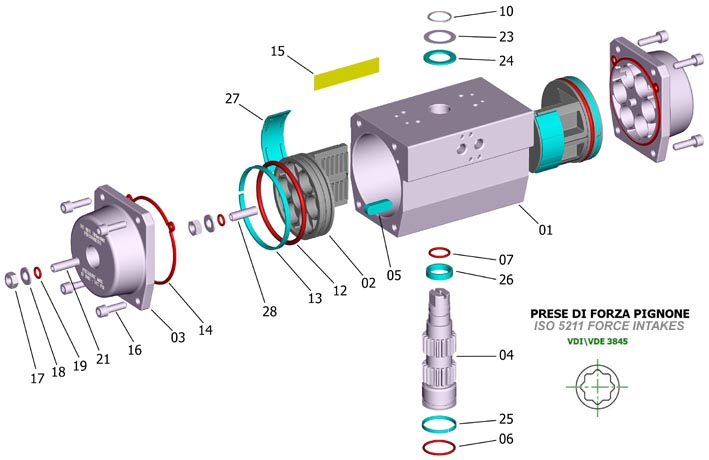

| POS. | DENOMINATION | PCS | MAT. |

|---|---|---|---|

| 1 | Body | 1 | ENAW 6063 T6 |

| 2 | Piston | 2 | ENAB 46100 T6 |

| 3 | Cover | 2 | ENAB 46100 T6 |

| 4 | Pinion | 1 | ASTM A105 |

| 5 * | Anti-ejection key | 2 | Resina Acetalica - Acetalic resin |

| 6 * | Pinion lower O-Ring | 1 | NBR |

| 7 * | Pinion lower O-Ring | 1 | NBR |

| 10 * | Seeger | 1 | Acciaio per molle - Spring steel |

| 12 * | Piston O-Ring | 2 | NBR |

| 13 * | Piston anti-friction ring | 2 | Resina Acetalica - Acetalic resin |

| 14 * | Cover Seal | 2 | NBR |

| 15 | Identification plate | 1 | Alluminio - Aluminium |

| 16 | Cover fixing screw | 8 | AISI 304 (A2) |

| 17 | Nut | 4 | AISI 304 (A2) |

| 18 | Washer | 4 | AISI 304 (A2) |

| 19 * | O-ring | 4 | NBR |

| 21 | Cover screw | 2 | AISI 304 (A2) |

| 23 * | Pinion thrust washer | 1 | AISI 304 (A2) |

| 24 * | Anti-friction washer | 1 | Resina Acetalica - Acetalic resin |

| 25 * | Inferior pinion guide ring | 1 | Resina Acetalica - Acetalic resin |

| 26 * | Superior pinion guide ring | 1 | Resina Acetalica - Acetalic resin |

| 27 * | Piston anti-friction pad | 2 | Resina Acetalica - Acetalic resin |

| 28 | Piston screw | 2 | AISI 304 (A2) |

| * | Spares kit |